Shop Explosion isolation proportional directly operated pressure-relief valve | Partsdic®

Explosion isolation proportional directly operated pressure-relief valve | Partsdic®

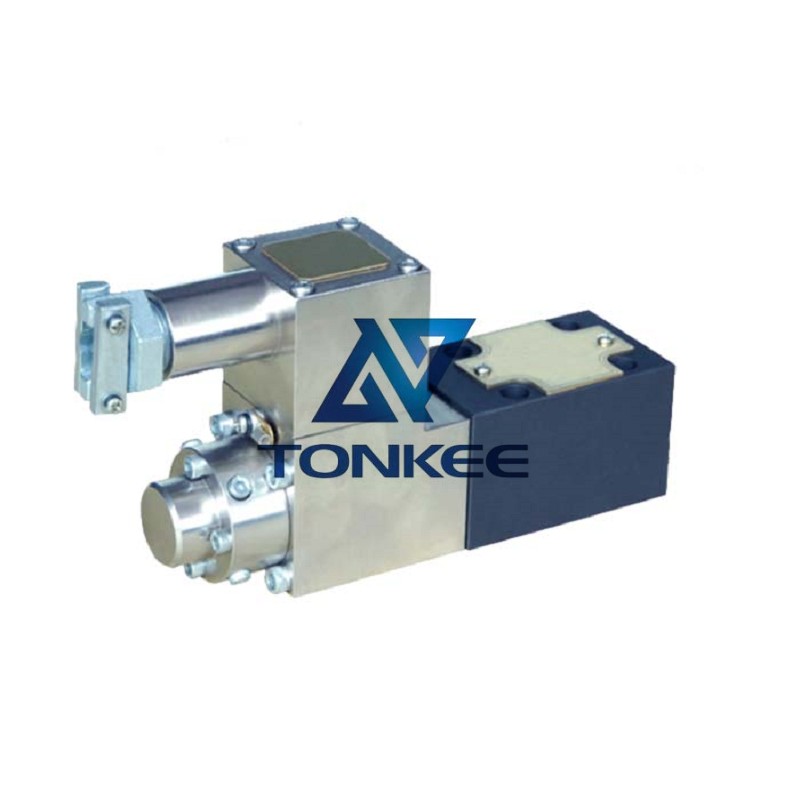

These valves are constructed from robust and corrosion-resistant materials to withstand harsh industrial conditions. Materials commonly used include stainless steel, brass, and high-strength alloys. The choice of material depends on the specific application and the nature of the substances being handled.

These valves are constructed from robust and corrosion-resistant materials to withstand harsh industrial conditions. Materials commonly used include stainless steel, brass, and high-strength alloys. The choice of material depends on the specific application and the nature of the substances being handled.

The Explosion Isolation Proportional Directly Operated Pressure-Relief Valve is primarily used to control and relieve excess pressure in industrial systems where explosive gases, vapors, or dust may be present.

The Explosion Isolation Proportional Directly Operated Pressure-Relief Valve is primarily used to control and relieve excess pressure in industrial systems where explosive gases, vapors, or dust may be present.