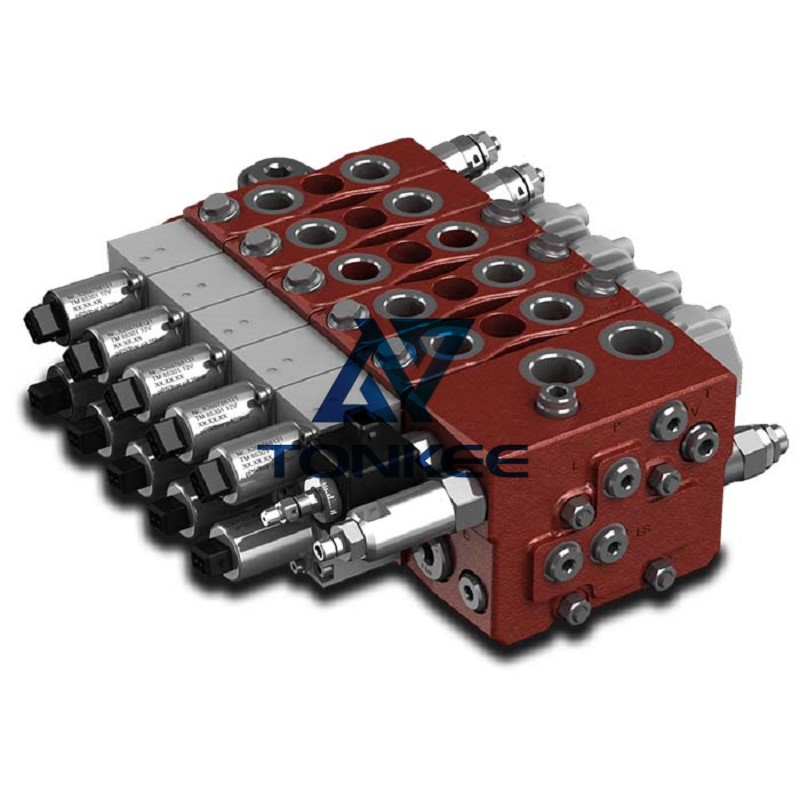

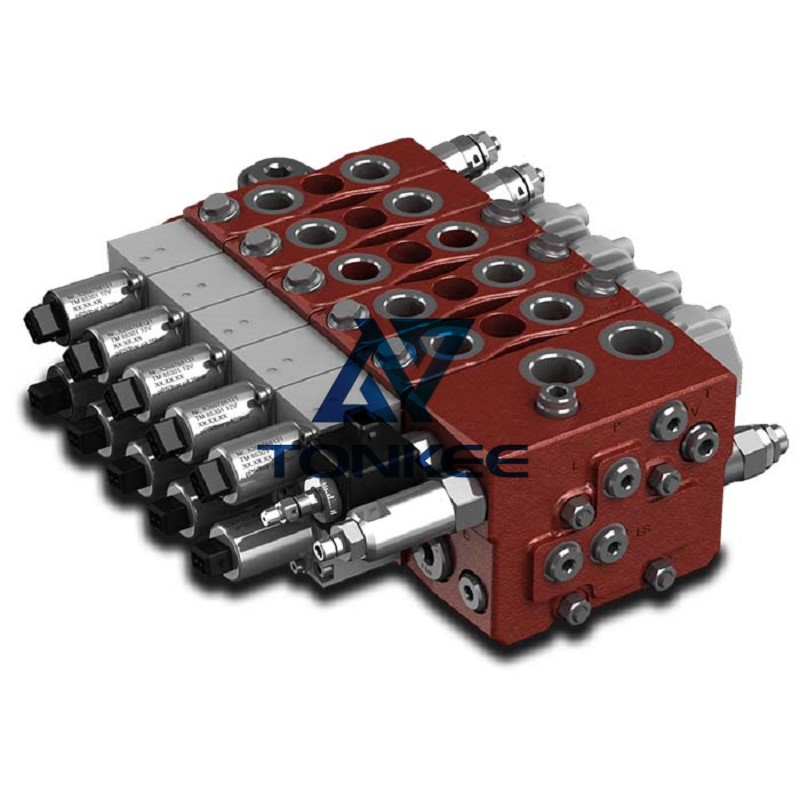

A 4-spool directional control valve is a type of hydraulic valve used for controlling the direction of fluid flow in a hydraulic system.

It typically consists of four individual spools, each responsible for controlling the flow of hydraulic fluid to specific actuators or circuits.

Spool Configuration:

The spools in a 4-spool directional control valve are arranged in a specific configuration to provide various operational modes. Common configurations include tandem, parallel, and series arrangements, allowing for different combinations of flow paths and functions.

Flow Capacity:

These valves are available in various flow capacities to match the requirements of different hydraulic systems. The flow capacity is typically measured in gallons per minute (GPM) or liters per minute (LPM) and should be chosen based on the specific application's demands.

Pressure Rating:

Pressure rating is a critical specification for any hydraulic valve. A 4-spool directional control valve should be capable of handling the maximum hydraulic pressure of the system it is installed in. Pressure ratings are usually denoted in pounds per square inch (PSI) or bar.

These valves can be actuated manually, electrically, pneumatically, or hydraulically, depending on the application. Manual valves are operated by hand, while electrically actuated valves are controlled by electrical signals. Pneumatic and hydraulic actuation involve using compressed air or hydraulic fluid to operate the valve.

Number of Positions:

A 4-spool valve typically has multiple positions, allowing for precise control of fluid flow. Common positions include two, three, or four-way configurations. Each position corresponds to a specific direction of fluid flow.

Mounting Style:

These valves come in various mounting styles, including subplate, manifold, and inline mounting.

The choice of mounting style depends on the system's design and space constraints.

Port Size:

The port size of a directional control valve refers to the diameter of the openings through which hydraulic fluid enters and exits the valve. Port sizes can vary, and it's essential to ensure they match the system's requirements.

Material and Seals:

Valve components are typically constructed from materials such as steel, aluminum, or cast iron, chosen for their strength and durability. The seals within the valve are crucial to prevent leakage and ensure proper operation. High-quality seals are often made of materials like Nitrile, Viton, or Polyurethane.

Spool Actuation:

Each spool can be actuated independently, allowing for precise control over the hydraulic system. Actuation methods may include manual levers, solenoids, or pilot valves.