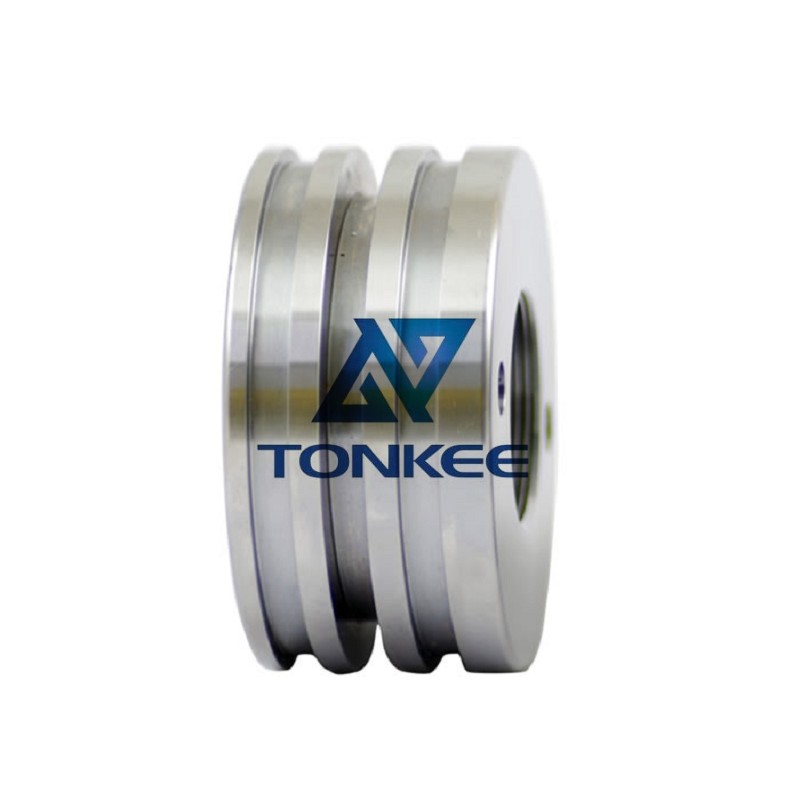

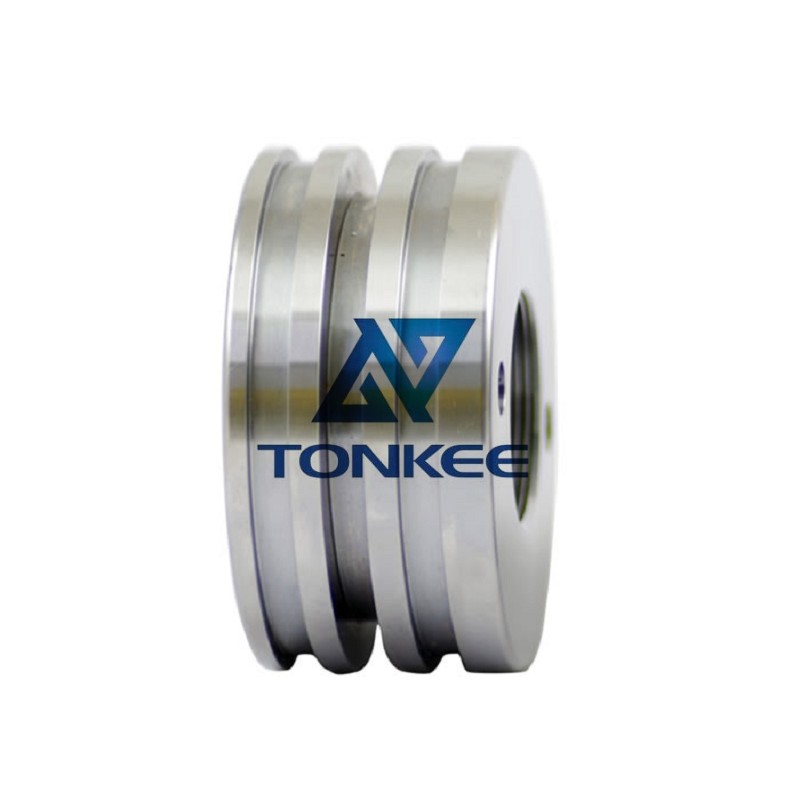

The choice of material for a threaded forged machined head bush is crucial to its performance.

Common materials include steel, stainless steel, brass, bronze, and aluminum. The material should possess properties like high strength, corrosion resistance, and wear resistance, depending on the intended application.

Size and Dimensions:

The size and dimensions of the bushing are determined by the requirements of the application. This includes the inner and outer diameter, length, and thread size. Precise measurements are essential to ensure a proper fit and secure connection between parts.

Thread Type and Pitch:

Threaded forged machined head bushes come with various thread types, such as metric, Unified National Thread (UN), or British Standard Whitworth (BSW). The choice of thread type should align with the mating components and the application's standards. The thread pitch, which defines the distance between threads, must also match to ensure a tight and reliable connection.

Head Design:

The head of the bushing is typically machined to provide a flat or contoured surface for proper seating and load distribution. The head design may include hexagonal, square, or custom shapes, depending on the application's needs. The head should be well-forged and machined to ensure strength and precision.

Tolerances:

Tolerances play a crucial role in the manufacturing of threaded forged machined head bushes. Tight tolerances ensure that the bushing fits securely and functions as intended. Common tolerance specifications include concentricity, parallelism, and dimensional accuracy.

Surface Finish:

The surface finish of the bushing is essential for preventing corrosion, minimizing friction, and ensuring ease of installation.

It is often specified in terms of Ra (arithmetical mean roughness) or RMS (root mean square) values. The choice of surface finish depends on the application's requirements.

Heat Treatment:

Depending on the material used, the threaded forged machined head bush may undergo heat treatment processes such as quenching and tempering to enhance its mechanical properties, including hardness and toughness. Heat treatment specifications should be carefully followed to achieve the desired material properties.

Coatings and Platings:

To improve the bushing's corrosion resistance and reduce friction, it may be coated or plated with materials like zinc, nickel, or chrome. The choice of coating or plating should align with the application's environmental conditions and requirements.

Load Capacity and Load Ratings:

The load capacity of a threaded forged machined head bush is a critical consideration, as it determines the maximum load it can support without failure. Load ratings provide valuable information about the bushing's capacity and are specified by manufacturers based on testing and analysis.

Quality Standards:

Manufacturers must adhere to specific quality standards and certifications, such as ISO 9001 or ASTM standards, to ensure the consistent production of high-quality threaded forged machined head bushes. These standards encompass material properties, manufacturing processes, and inspection procedures.

English

English Türkçe

Türkçe